Technical snow

Outdoor production of technical snow

Technical snow is also produced according to the same physical laws as in nature.The difference to nature is that the water required for snow production is sprayed under pressure and is ejected on the slope via a nozzle or a lance.

The water drop has only a few seconds flying time on its way from the nozzle to the slope. Energy sources in form of undercooled water drops are added to the water via special nozzles similar as it is done in nature. These undercooled water drops join the remaining water during a short flying time and form the requested “technical snow”.

Technical snow can be produced in different volume and quality at air temperatures below approx. 2°C, depending on relative humidity and water temperature. Thus, the wet-bulb temperature which is the ratio between air temperature and relative humidity is decisive for the technical snow production.

The alpine snow producers perform maximal snow production at a wet-bulb temperature below -12°C.

Even more, these additives are not allowed to be used in the German-speaking alpine region and do not comply with the ecological fundamental idea of our society.

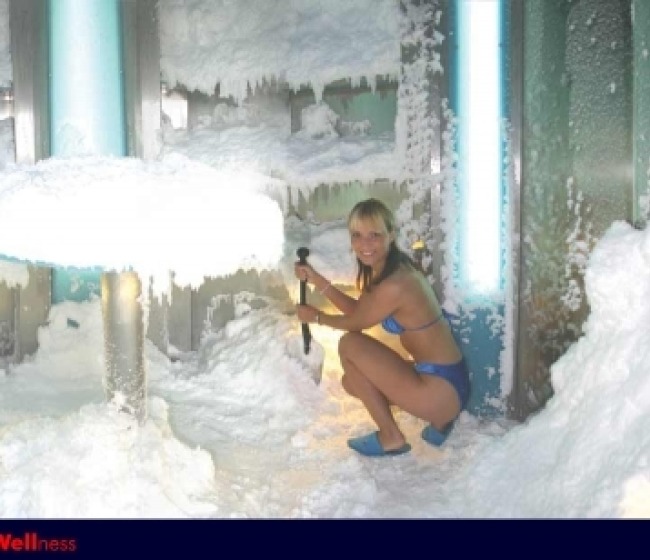

Indoor production of technical snow

Innovag Snow Systems are not based on conventional systems, but is characterised by a fundamental patented new development.

The new development of the indoor snow technique was necessary as the high expectations and demands of our industrial customers could not be satisfied

with conventional indoor snow systems.

Feasibility studies for the automobile industry or special demands for test benches of railway components already inspired the Innovag AG years ago to investigate the facets and the limits of feasibility of the snowing technique.

The results of this research and development work were implemented successfully in industry. These, in turn, led to the fact that, for example, the Deutsche Bahn declared this technique as “state-of-the-art” in the division of material testing for brake facings.

The high demands of the industry for quality and the reproducibility of the produced snow as well as the high availability of the Innovag snow producing systems prompted the Innovag AG to install this technique and with it, the experiences gained also in indoor facilities for winter sports, wellness & spa as well as for recreational facilities.

Features Innovag Snow Systemes

The production of dry, powdery snow is the basic requirement for brake test benches or for the production in air-conditioned wind tunnels.

The production of wet snow is an easy task. If only wet or very moist snow can be produced, then you have to live with ice. This is quite natural. When a water droplet instead of a snow grain falls to the ground, then it can never turn to snow again.

The Innovag snow system converts already a few centimetres of water into snow. Very tiny snow parts are formed or if requested also tiny snow flakes.

These snow flakes build up a snow cover on the ground as well-known from nature. The Innovag Snow Systems can manage to produce snow with a density of 100 kg/m³ up to 250 kg/m³. This means that snow can be produced with the Innovag Snow Systems in any quality requested - from powder snow as found in nature only under most ideal conditions up to moist snow.

The optimal snow quality is a precondition for top athletes as well as for leisure time athletes to go in for sports.

It is the learner for whom it is very important to train on perfect slopes so he does not lose enthusiasm when he has to exercise his first swings on icy slopes. He gets a wrong picture from the fascination of winter sports.

Nature can compensate poor snow quality by fascinating sceneries and magnificent mountains. However, when exercising indoor winter sports the facets „exercising sports“ and “fascination snow” are the real focus.